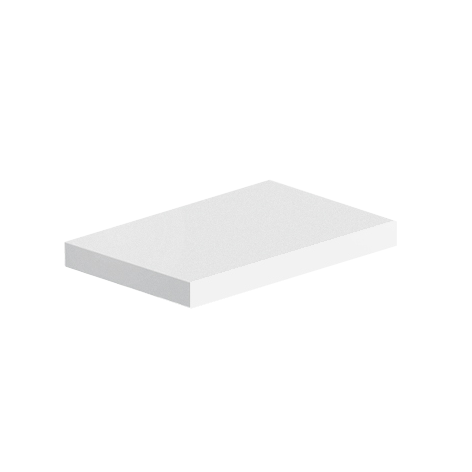

SPA CUSHION 900

SPA SEAT CUSHES

The Cleopatra spa seat cushion makes showering and steaming truly comfortable.

The seat cushion is specially designed for use in humid and hot environments such as steam rooms, showers, spas and bathrooms.

The seat cushion is easy to keep clean with a cloth and detergent.

At the bottom of this page you will find the documentation related to maintenance and safety.

The dimensions of the seat cushion: 900 (L) x 400 (W) x 50 (H) mm.

This (steam) shower seat cushion is available in 4 different colors:

White: RAL 9016

Gray: RAL 7042

Black: RAL 7021

CLEANING ADVICE

Click here: Spa furniture maintenance advice

COLOR

Available in other RAL colors upon request; would you like to receive this cushion in a different size? Please contact us.

MATERIAL PROPERTIES

Spa Furniture coating has some great features, such as:

- Very few chemicals have any effect on the chemical bonding of silicon molecules. This means that almost no material sticks to silicon. Even ballpoint markings can be easily removed from the coating.

- Cold- and heat-resistant. The silicon molecules are stable between -50 and +300 degrees Celsius.

- Silicon is a very skin-friendly product. Most cosmetics such as skin creams, lipsticks, etc. contain silicon

- Silicon is UV resistant

- Silicon is recyclable

- The Spa Furniture products are very comfortable to the touch, soft and very flexible.

- No VOCs are used for the coating process.

- Minor damages can be repaired on site.

SUSTAINABLE

Spa furniture coating consists of silicon, the raw material for silicon is sand. Sand is readily available

on the surface of the earth so one need not drill deep into the ground to obtain it, such as

for example, petrochemical-based coatings such as polyurethane. Mining silicon is less

taxing on natural resources. This means that for the production of silicon, less water,

raw materials and energy required compared to PU and PVC products.

BESPOKE WORK

In addition to the products in the catalog, it is possible to produce customized products; both in terms of shape

as color. In doing so, we work closely with clients, architects and designers. Together with these

parties we form design ideas into a product, which can be cut by a CNC-controlled

foam cutting machine.

After the foam is cut to the agreed specifications, we can begin coating.

In this process, the coating is manually applied to the open structured piece of foam to create a

create mechanical adhesion to the foam. This coating seals the foam and provides a

flexible and soft leathery skin.

UNIQUE CHARACTERISTICS

- Durable

- Production process without VOCs

- Water and steam resistant

- Cold and hot resistant

- Easy to clean

- Soft Touch

- UV resistant

- High elasticity and lasting flexibility

- Recyclable

- Customized shape and Color (RAL)